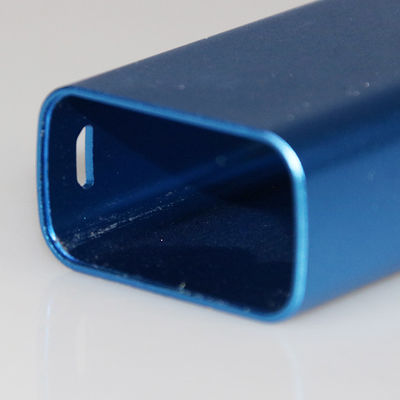

Aluminum Alloy Custom Cnc Machining Center Cnc Machine Power Shell

Company introduction

Our company specializes in providing mobile phones and digital products metal appearance decoration parts, metal structural parts research and development and precision manufacturing, the company's products are mainly applicable to consumer electronics digital products, camera lenses, 3D printer accessories, smart bracelet buckles, 5G communication products, medical equipment, biotechnology, testing equipment, automotive equipment, etc. The company was founded in 2004, located in Guanlan Street, Longhua District, Shenzhen, the existing plant area of more than 1000 square meters, employing more than 50 employees, development, process engineers 10 people, the company with advanced production equipment, strong technical force and perfect quality management system, to provide customers with quality products and services. Turning and milling: all kinds of aluminum profiles, turning parts, etc., can process a variety of materials (including iron, copper, aluminum, stainless steel, galvanized sheet, etc.); The company's main equipment includes: automatic lathe, CNC lathe, CNC machining center, engraving machine, CD machine, sawing machine, punching machine, grinding machine, milling machine, etc., post-processing color printing, oil injection, oxidation, electroplating one-stop service.

| Equipments |

CNC Machining Lathe |

33 sets |

±0.005mm |

φ0.5mm- φ150mm*300mm |

| CNC Milling Centre |

200 sets |

±0.01mm |

510mm*1020mm*500 mm |

| Metal Working Machines |

42 sets |

±0.01mm-0.1mm |

3000mm*2500mm*1 mm |

| Material |

Steel:1018,1213,12L14,1215,C45, etc. |

| Available |

Stainless Steel:201,301,303,304,316,416,420, etc. |

| |

Aluminum Alloy:5052,6061,6063,6082,7075,etc |

| |

Brass Alloy:360,36000,3601,3602,3603,3604,38500, etc. |

| |

Bronze:C51000,C54400, etc. |

| |

Plastic: Pom, ABS,Nylon, etc. |

| Treatment |

Anodize, sandblast,polishing,nickel plating,electroplating,annealing,chrome plating, laser etc. |

| Inspection |

CMM, Projector,Alimeter,Roughness tester, Micrometer, Caliper,Block gauges,etc |

| Equipments |

| Advantages |

10 years profession custom cnc machining service experience. |

Product show

Company show

Office

HeRong intelligent equipment co. Ltd. has an office area of 1000 square meters. We have a complete service and production team. Include 15 sales teams, 9 engineers, 5 design teams, 8 R&D teams, more than 100 production and quality inspection teams, and 16 administrative and logistics teams. Our team works closely and is confident to provide customers with one-stop service from design to mass production.

Work shop

The factory area of Herong is 11000 square meters. And has powder metallurgy, injection molding, aluminum alloy die-casting, oil injection and other complete production lines. This is the basis for providing best services to customers. With professional staff, we can provide customers with the most cost-effective production solutions.

Surface treatments

After finishing the processing technology of products, we will provide corresponding surface treatment methods according to the needs of customers. Such as anodizing, electroplating, oil spraying, powder spraying, etc. To improve the appearance and beauty of the product and its service life.

FAQ

1. who are we?

We are based in Zhejiang, China, start from 2014,sell to Eastern Europe(70.00%),Central America(18.00%),North America(12.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

cnc milling part,bearing block,aluminum plate,metal hook,off standard part

4. why should you buy from us not from other suppliers?

XU HANG is a factory have CNC machines and Numerical Control Machinery,especially produce milling products, aluminum plate bearing block and other off-standard product. We can make your products according to your drawings and samples.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!