| 316L |

Powder Metal Sintered |

Commen used Austenitic stainless-steel with good corrosion resistance. |

Medical technology device, Surgical instruments,aviation, jewellery or consumer goods industry. |

| 17-4 PH |

Metal Injection Moulding |

Martensitic, precipitation hardening stainless steel with high strength and corrosion resistance. |

Application examples: plant engineering, aerospace and consumer goods industry. |

| 430 |

Metal Injection Moulding |

Ferritic, heat-resistant and corrosion-resistant stainless steel. |

Household and kitchenware, mechanical engineering, electronics and food industry. |

| 440C |

Powder metallurgy |

Corrosion resistant, hardenable steel with high strength and wear resistance. |

Application examples: plant engineering, cutting tools, spray nozzles, medical technology, roller bearings. |

| Ti Grade 2 |

MIM |

Unalloyed titanium with low density, high corrosion resistance and excellent biocompatibility. |

Application examples: Chemical industry, aviation, medical technology. |

Company and products

Herong Intelligent Co, Ltd. specializes in the production of powder metallurgy products. It mainly includes oil bearing, powder metallurgy gear, structural parts, etc. The company has modern production equipment, perfect testing instruments, experienced scientific researchers, and a complete and scientific quality management system. It can be produced according to national standards and relevant international standards.

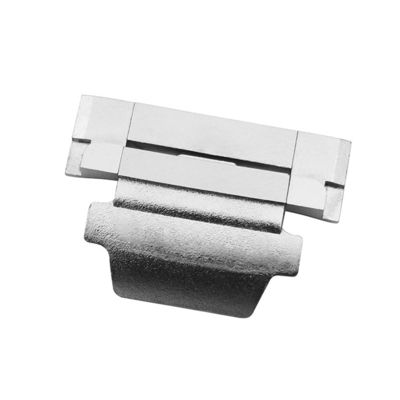

Product show

Company show

Office

HeRong intelligent equipment co. Ltd. has an office area of 1000 square meters. We have a complete service and production team. Include 15 sales teams, 9 engineers, 5 design teams, 8 R&D teams, more than 100 production and quality inspection teams, and 16 administrative and logistics teams. Our team works closely and is confident to provide customers with one-stop service from design to mass production.

Work shop

The factory area of Herong is 11000 square meters. And has powder metallurgy, injection molding, aluminum alloy die-casting, oil injection and other complete production lines. This is the basis for providing best services to customers. With professional staff, we can provide customers with the most cost-effective production solutions.

Surface treatments

After finishing the processing technology of products, we will provide corresponding surface treatment methods according to the needs of customers. Such as anodizing, electroplating, oil spraying, powder spraying, etc. To improve the appearance and beauty of the product and its service life.

FAQ

How long can i get the feedbacks after we sent the inquiry?

We will reply you within 12 hours in working day.

How does your factory do regarding quality control?

Quality is priority." Our team always attach great importance to quality controlling from the very beginning to the very end.

What is the accuracy of the products processed by the drawings?

Different equipment has different accuracy, generally between 0.05-0.1

What certifications or qualifications does your company have?

Our company’s certificates are: ISO, ROHS, product patent certificates, etc.

Can injection products be surface treated? What are the surface treatments?

It is ok. Surface treatment: spray paint, silk screen,electroplating, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!